Aircon – some interesting facts

I live in the tropics so the aircon is very important, I now have constant vent temps of 6.6C to 7.7C while outside road temps show 33C , I’ve learnt a few things while making my aircon efficient, here’s what I’ve discovered.

My vette was converted to Right Hand Drive and at the same time to R134 gas . It has the C68 climate control.

The first thing I did to maximise the efficiency of the aircon was to disconnect the heater hoses. I have never needed the heater in Cairns.

I was disappointed with the airflow from the blower – I fitted a new blower and it drew less amps than the old blower, but the airflow was EXACTLY the same – about half what’s needed. I have heard that newer Japanese blowers move more air but haven’t found a suitable one yet. Auto electricians tell me I’m looking for more speed, which makes sense.

I took the dash apart – found a beer bottle top, half blocking a disconnected air vent tube, and a few other problems like that. All legacies from the RH Drive conversion. The Air box is moved from RH to LH side during the conversion and also inverted. I cleaned out the evaporator because when new, they have a sheet of foam in front of them and this melts/deteriorates over time, especially in hot climates. I fixed several air leaks from poorly sealed joins etc.

I fitted a dual digital thermometer, from Dick Smith Electronics, so I could measure the centre vent temperature and the cabin temps – and get an accurate view of what was happening.

There is an adjustable inline screw, beside the evaporator box, that sets the low pressure going into the evaporator. In my attempts to get colder air, I turned it down very low, (anticlockwise,1/2 turn) but the evaporator iced up. The signs were the vent temps going from a nice 9 or 10C and rising to past 22C – always fixable by leaving the fan on and turning A/C off so it could thaw out. I turned it the other way (1/2 turn clockwise) and the vent temps were not cold enough- 12 – 13C, and still the evaporator eventually iced up, sometimes after an hours driving.

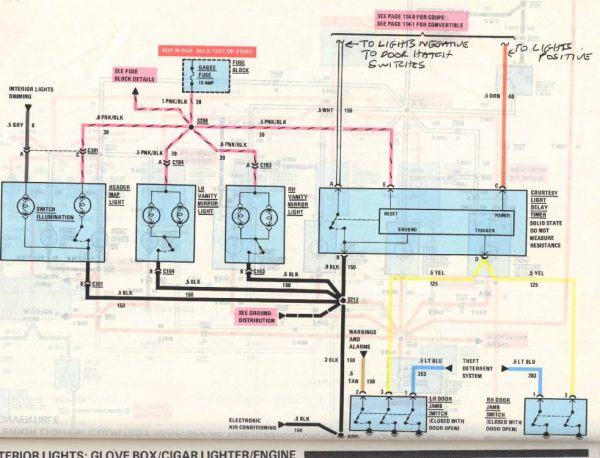

I also found that when the car was parked and hot, upon restarting, hot air would blow from the vent until the car was moving – the inline coolant fan switch was not working – it should turn the coolant fan on when the aircon is turned on, so that air flows across the accumulator, in front of the radiator. I fitted a manual switch to turn the fan on and this solved that problem until I replaced the switch.

Arrow points to the switch which is in the gas line running along between the radiator and the front of the engine and

I had the gas checked to make sure the pressure was correct.

The aircon box is in two halves and I found some major leaks on the engine side of the firewall, where the aircon box joins had split open. I also found two oblong section air tubes under the dash, venting air into the dash cavity – if they were a bit longer, that air might have reached the foot well, but the size of the pipe was too extravagant for the amount of moving air. First priority, for me, is to blow cool air on chest and face – then onto feet. So I partially blocked them –I also found the heater door was not completely closed.

After I sealed these significant air leaks, the blower on ‘full’ was now giving maybe 7 out of 10 airflow. I then discovered that this had cured the frozen evaporator problem and stopped it icing up.

By this stage I saw the incredible vent temps of between 6.6 and 7.7C, and no icing up of the evaporator. Aircon mechanics are happy to set the vent temps at 10C so this is a significant achievement. I can only assume that fixing the air leaks and closing the heater door increased the airflow through the evaporator.

When the vette has been parked in the sun, it takes over 30 minutes to cool it down, because the fan doesn’t shift enough air, so I’m still on the lookout for a better fan

Two other things I have discovered are – if the blower only blows full speed, an inline fuse, under the hood, near the bulkhead has blown – I replaced mine with a 15 amp fuse and have had no further trouble.

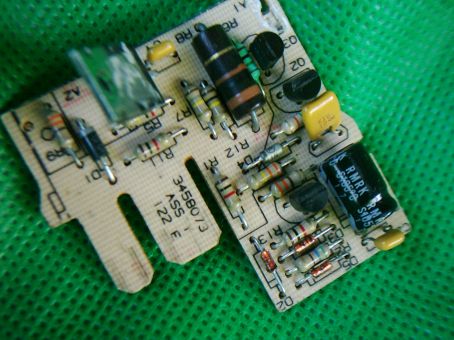

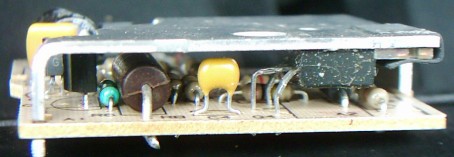

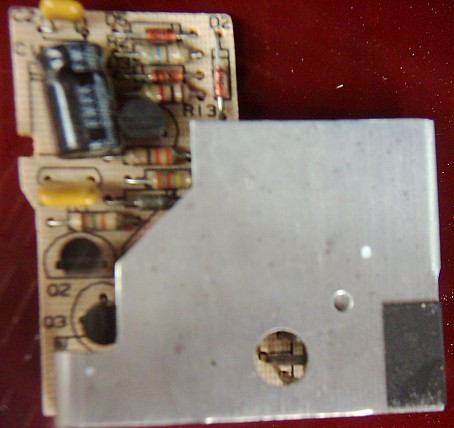

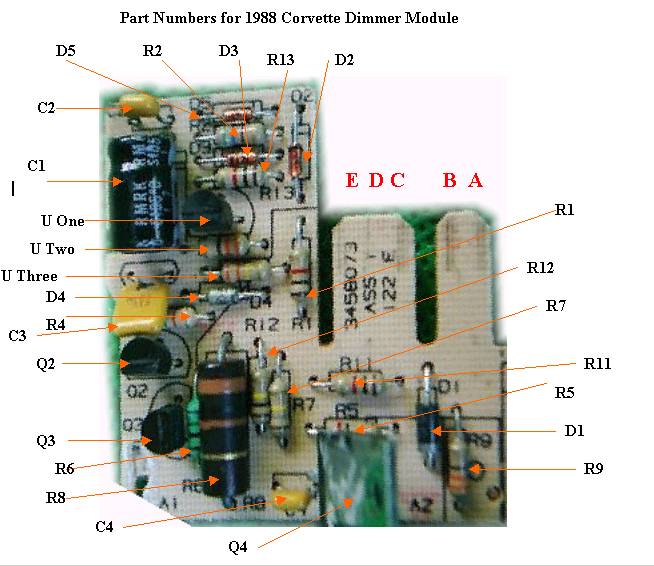

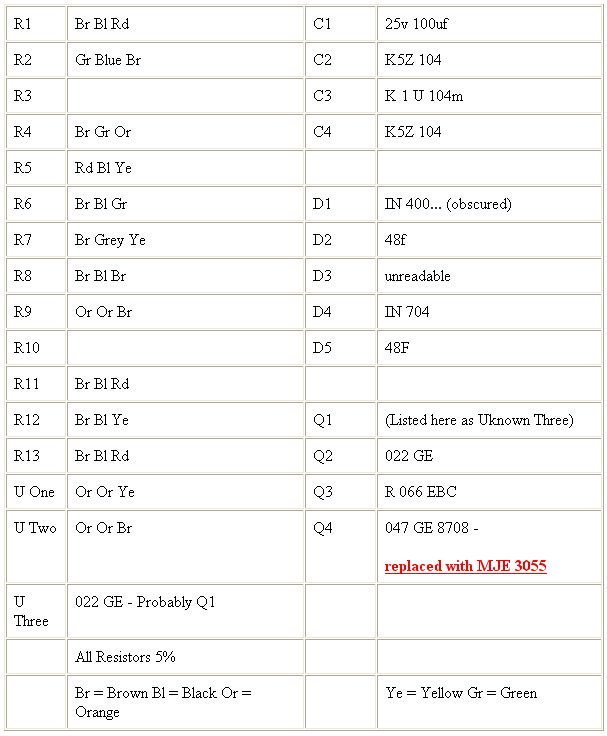

One day the blower was stuck on, even with the ignition key out – the blower module had failed.

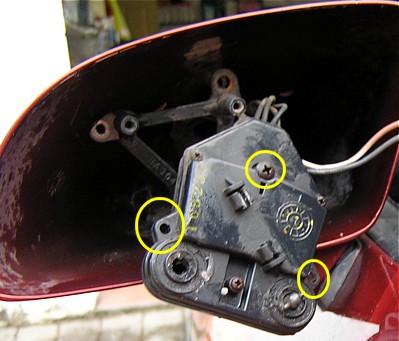

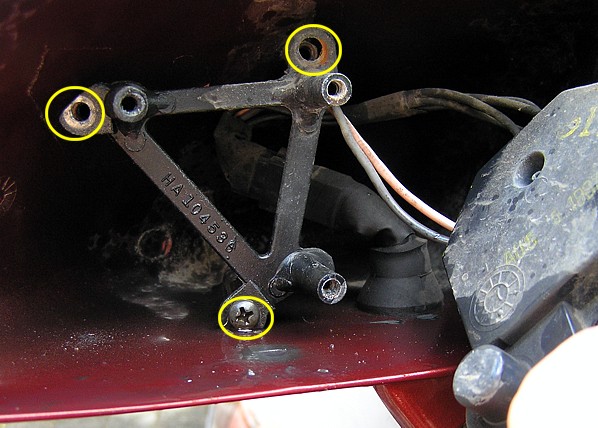

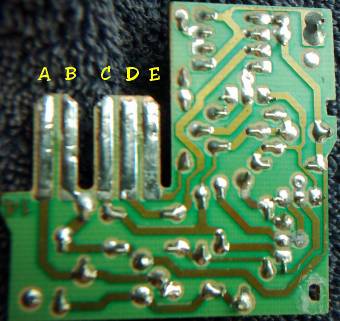

On LH drive cars, the module is on top of the aircon box, so on RH drive cars it’s on the bottom and not so easy to replace, with the chassis close underneath it.

This is the view when laying on the ground looking up at it!!!

I got some great help from the Corvette Forum, including two NSW Aussie vette owners – rodj and Aussie Vet .

I’d like to say a very special THANK-YOU to the Corvette GURU on airconditioning, whose username on the Corvette Forum is SunCR. Many many thanks Bill, for your hours of help as we’ve worked through my aircon system .

To sum up – check the gas pressure. Clean the evaporator which probably is clogged with foam that has deteriorated over time, make sure the radiator fan comes on when the aircon is turned on. Make sure the heater door closes properly- that’s VERY IMPORTANT. Look for air leaks. Have the adjustable screw correctly adjusted.