2006 January – fitted new module for the blower motor and Aircon.

Located and sealed several air leaks from the heater/aircon box and vents. Result was very good, with more cool air blowing from the vents. Digital thermometer in the air vent registered 6.7C – an excellent cold temperature.

Fitted new C68 Climate control Module.

April – fitted 2nd Hand ECM. Everything worked as normal, so I now have a spare to use for testing.

In preparation for a long drive to Brisbane and back, estimated at 4-5000kms (3000+miles), I tackled several jobs –

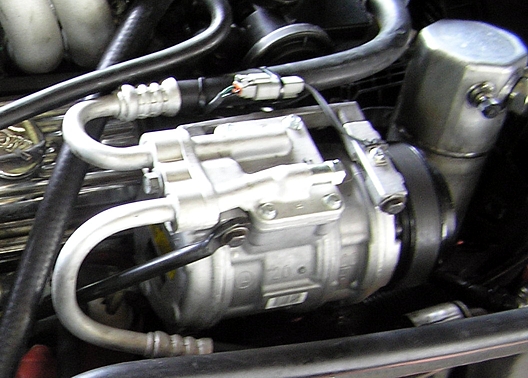

The hydraulic lifters were not adjusted properly after the heads were reconditioned last year. It took me nearly 3 hours to remove the right-hand rocker cover because of all the parts like the airconditioning compressor that were in the way, and because of my bad back I could only work for short periods, but within a few days I had the lifters adjusted properly and everything back together.

The next project was to remove some excess padding from the passenger seat side bolsters, which had been added in error when I had the seats recovered. That was an easy job.

My back is partially fused together and very stiff. That, and my height, make it hard to get into the vette seat, so I have lowered the seat as much as I can. It’s so low that I was sitting on some of the adjusting machinery. The main culprit was the power reclining mechanism.

After some research I discovered that the manual reclining mechanism was less intrusive, so I ordered one of those from Vette2Vette in America.

For a long time the windscreen had been leaking in heavy rain. Eventually I found the source of the leak, between the glass and metal trim. I cleaned out the old silicone and resealed both sides.

A simple job was changing the oil and filter – or so I thought at the time, so I left it to last.

Another job on the list was fixing the door locks. On the passenger side the key would not operate the lock, and on the drivers side the electric solenoid was stiff, preventing the remote locking system from working.

Working inside the passenger door was tricky. The lock is at the top rear corner and mostly I had to work one handed and unsighted. It was while I was stretched and twisted trying to re-fit a circlip that I wrenched something in my spine which gave me a massive spasm and has been causing me pain ever since, despite many trips to the physiotherapist.

After losing the circlip in the door several times, I supaglued some thread onto it and of course it fitted straight on the next go!

On the drivers side I drilled out the rivets holding the power door lock solenoid in place. Took the solenoid apart and discovered it’s a motor not a solenoid.

Cleaned it and the door lock up and bolted it back into place.

While working on the car one of the headlight lids came loose. I had it re-glued with expensive panel adhesive and I also attached a safety wire so that if one came loose again it wouldn’t fly off the car.

The steering rack had begun to leak, so I booked the car in with the steering rack specialists. What started out as a 2 day job turned into an 11 day saga. Firstly, because of the Right Hand Drive conversion, the rack is not a Corvette one and couldn’t be identified. The vette was converted by Corvette Queensland so I rang them to ask what the rack was from. They told me they didn’t know, but could sell me another one……. Hmmmmm.

Eventually the seals etc were sourced and the rack reconditioned. When they were refitting it I was told that the steering hadn’t been centered correctly during the conversion. I finally picked the vette up on a Sunday morning, with just a week to go before our planned holiday. The steering wheel was 1/3rd of a turn out and the specialists advised me that was because they had ‘re-engineered’ the rack so that it was centered. They also said I would have a tighter turning circle.

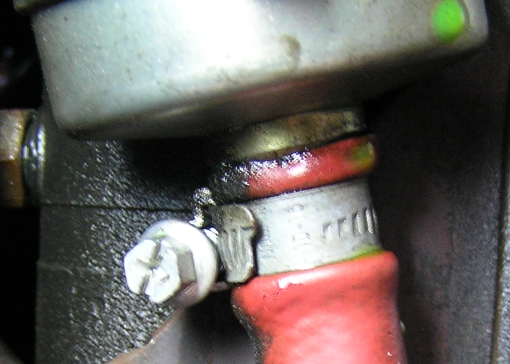

Cause of the rack leaking was traced to the rubber boots which were continually sucking in air and dirt as they compressed and decompressed. Pinks workshop did an excellent job of re-engineering the rack, fitting breathing tubes between the rubber boots, new rack ends, re routing new hoses etc.

I noticed that the indicator wouldn’t cancel on one side, so I dismantled the mechanism inside the steering column but found it was not adjustable. I then had a lot of trouble refitting everything, eventually I made a ‘pusher’ from the steering wheel puller and managed to squeeze the spring back down and fit the C clip.

I noticed some oil leaking from the new rack so took it back, but the workshop couldn’t find a leak, they did notice a blob of green coolant and suggested that maybe the coolant was leaking, so I hurriedly drove round to the radiator shop. Time was running out and if something needed fixing I only had one day, Friday, left to organise it.

They pressure tested the system and could find no problem. The leak must have been caused by oil residue because it hasn’t leaked since. I felt very confident that the coolant system would give no trouble after the pressure test.

Other jobs included hiding spare keys, replacing blown globes in the 3rd brake light, having a wheel alignment, re-set camber, wheels balanced.

Our plan was to leave early on Sunday morning, but while I was doing last minute jobs on Saturday afternoon, I discovered that the sump plug was loose and that the thread was partially stripped in the sump. I had the hole tapped one size oversize and was very pleased to see how thick the metal was in the sumpplug area.

The trip was a big success – see the Motoring Holiday 2006 page.

back to top